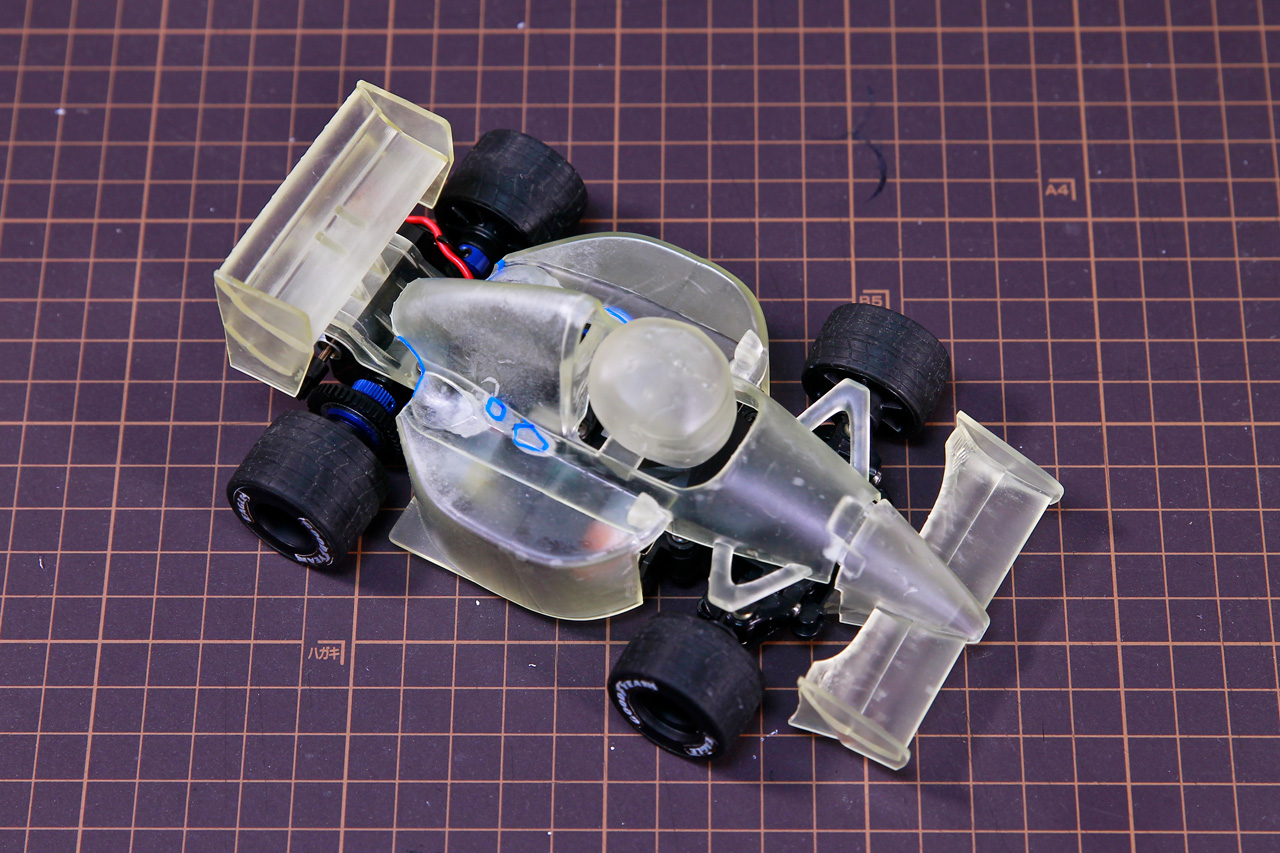

F91開発は最終段階に入り、いよいよ製品に向けた最終調整へ──。石川さんから「F91の試作に入りますね~」と連絡が入ったのですが、それとほぼ同時に設計変更を伴う思いつきがありました。簡単にアイデアを伝えたのち、試作は中断。こちらは改良を施されたマシンの仮出力品になります。

F91 development entered its final stage, and we were finally making final adjustments for the product…. Mr. Ishikawa contacted me and said, “We are going to start the prototype of the F91…” At about the same time, I had an idea that involved a design change. After a brief presentation of the idea, the prototype was halted. This is a temporary output product of the improved machine.

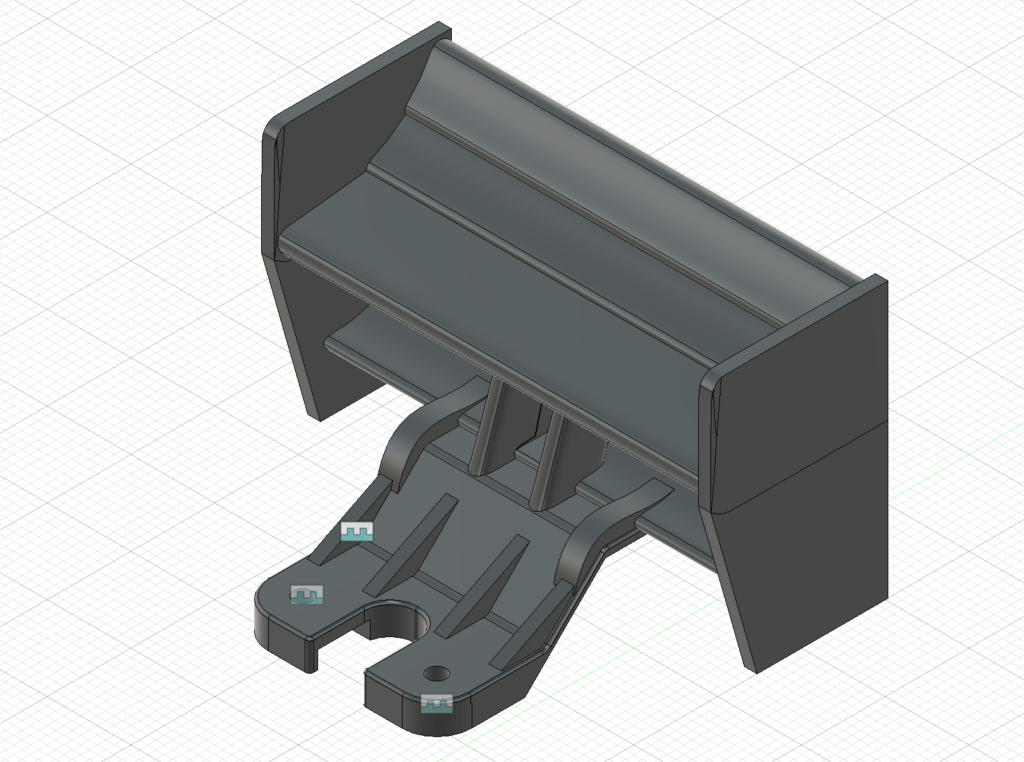

違いはリヤウイングのマウント方法です。別の開発をやっている最中に「あれ?この穴ってリヤウイング使えるんじゃない?」と、ダンパーポストの2つの穴に目が止まったのが新ウイング誕生のきっかけ。作ってみると、なんでこれに気づかなかったのか?! と思うくらい。

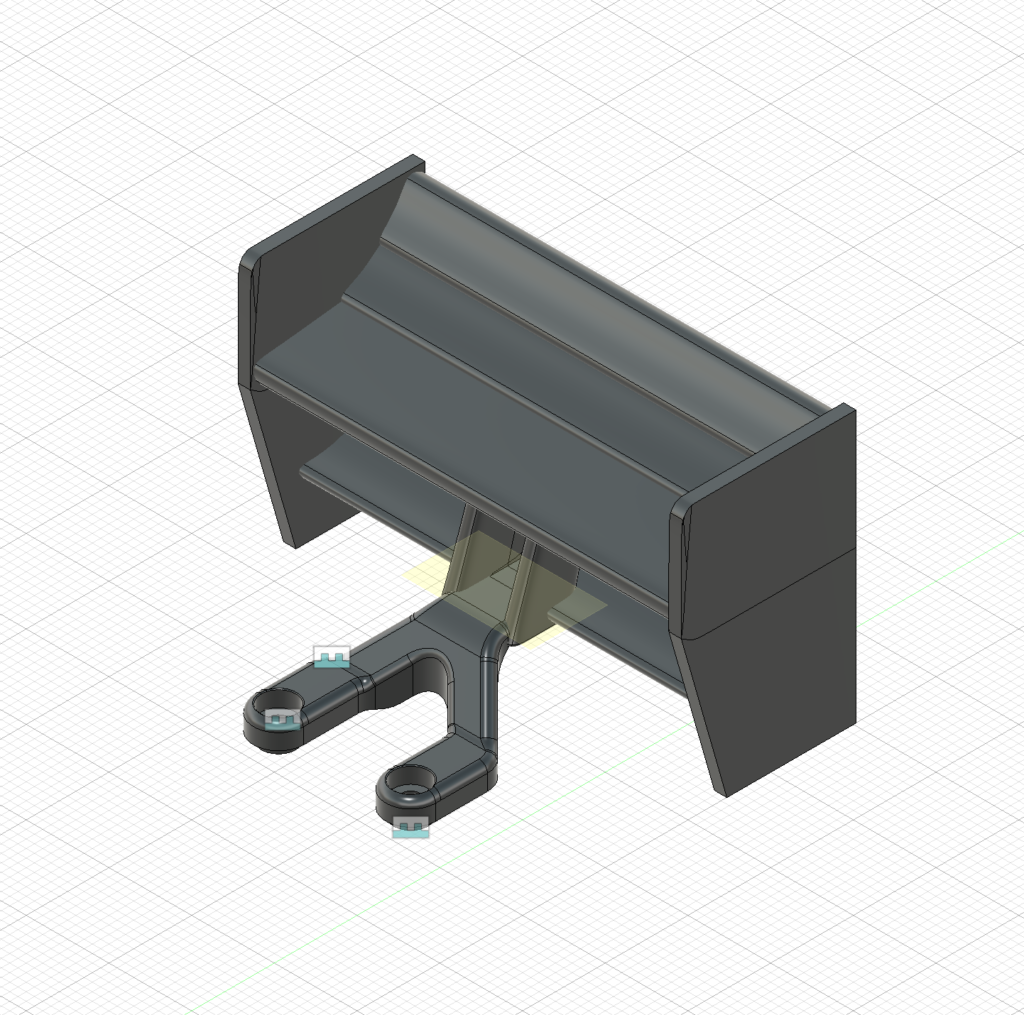

最初に思いついたのはこんなカタチ。ただこれだと、ピッチング時にカウルのリヤエンドがすぐに干渉してしまいます。

While we were working on another development project, I thought, “Hey, can’t I use this hole for the rear wing? Couldn’t these holes be used for the rear wing?” The two holes in the damper post caught my eye, and that was the beginning of the new wing. After making the wing, I wondered why I had not noticed them before.

The first shape I came up with was like this. However, with this shape, the rear end of the cowl immediately interfered with the additional mount when pitching. I tried to find a way to make the area in front of the motor where the stay goes down thinner and closer to the finished model.

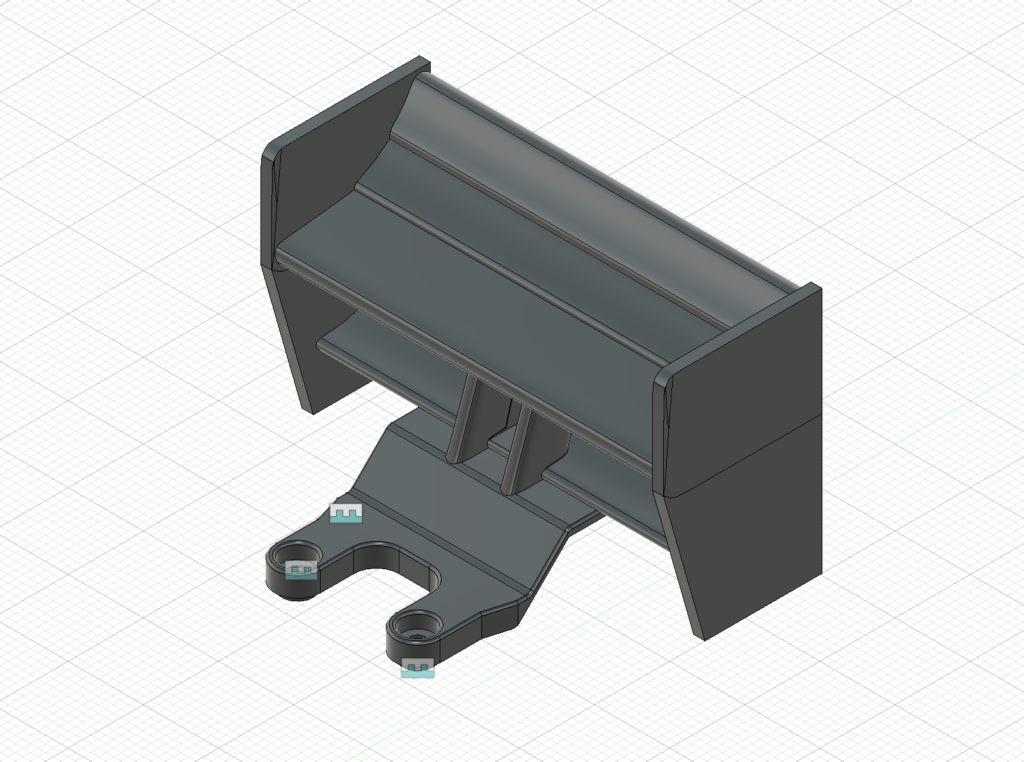

なんとかモーター前面の、ステーが下る部分を薄くできないか工夫して完成系に近づいていきましたこれは石川さんのモーターホルダーの補強方法から思いついたバージョン。

This idea came from Mr. Ishikawa’s method of reinforcing the motor holder, which was a different shape at first.

最初の2案ではダンパーポスト周りが高くなって、ボディに大きく干渉。少しでも高さを下げる工夫をしたものの、今度は薄板部分が長くなるので補強するなど。

In the first two proposals, the area around the damper post was higher and interfered with the body significantly. We tried to lower the height a little, but this time the thin plate part became longer, so I reinforced it.

とりあえずいい感じなので、走行テストかな

It looks good for now, so I guess it’s time for a driving test.